SOLUS

KNOWLEDGE CENTER

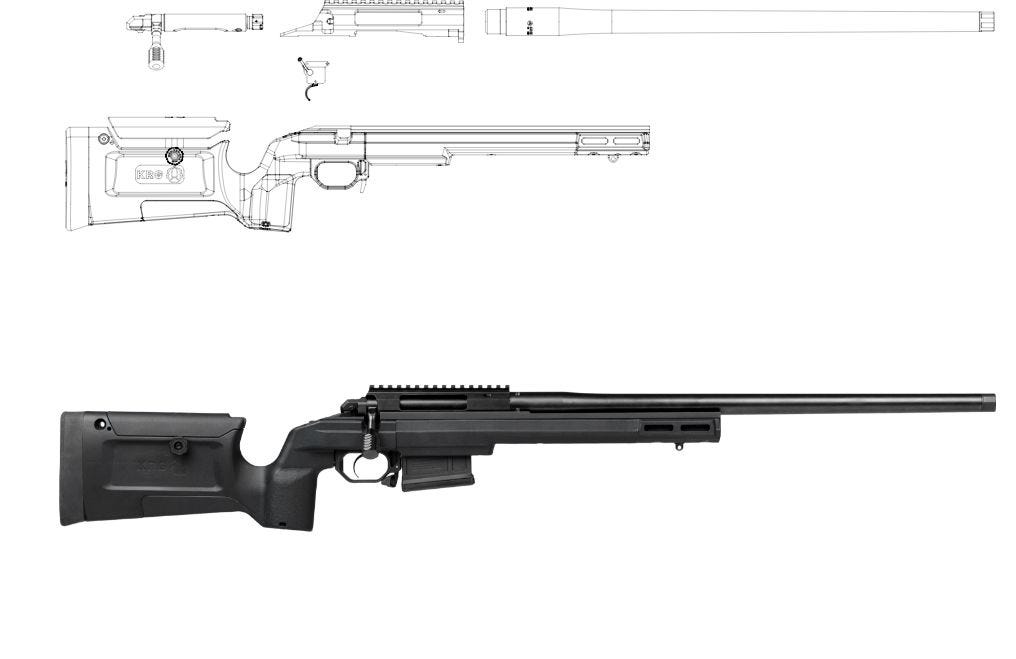

SOLUS

COMPETITION RIFLE TECH SPECS

SPECIFICATIONS

KEY ATTRIBUTES

- Action: SOLUS Short Action

- Chassis: SOLUS Competition Chassis

- Trigger: SOLUS Single Stage

- Caliber: 6 Creedmoor, 6.5 Creedmoor, 308 WIN

- Magazine: AICS/AIAW detachable box magazine

FEATURES

- 60-degree bolt throw

- Integral 20 MOA bias scope base

- Adjustable cheek comb, length of pull, and recoil pad cant

- M-LOK/Arca compatible forend

KEY ATTRIBUTES

- Action: SOLUS Short Action

- Chassis: SOLUS Competition Chassis

- Trigger: SOLUS Single Stage

- Caliber: 6 Creedmoor, 6.5 Creedmoor, 308 WIN

- Magazine: AICS/AIAW detachable box magazine

FEATURES

- 60-degree bolt throw

- Integral 20 MOA bias scope base

- Adjustable cheek comb, length of pull, and recoil pad cant

- M-LOK/Arca compatible forend

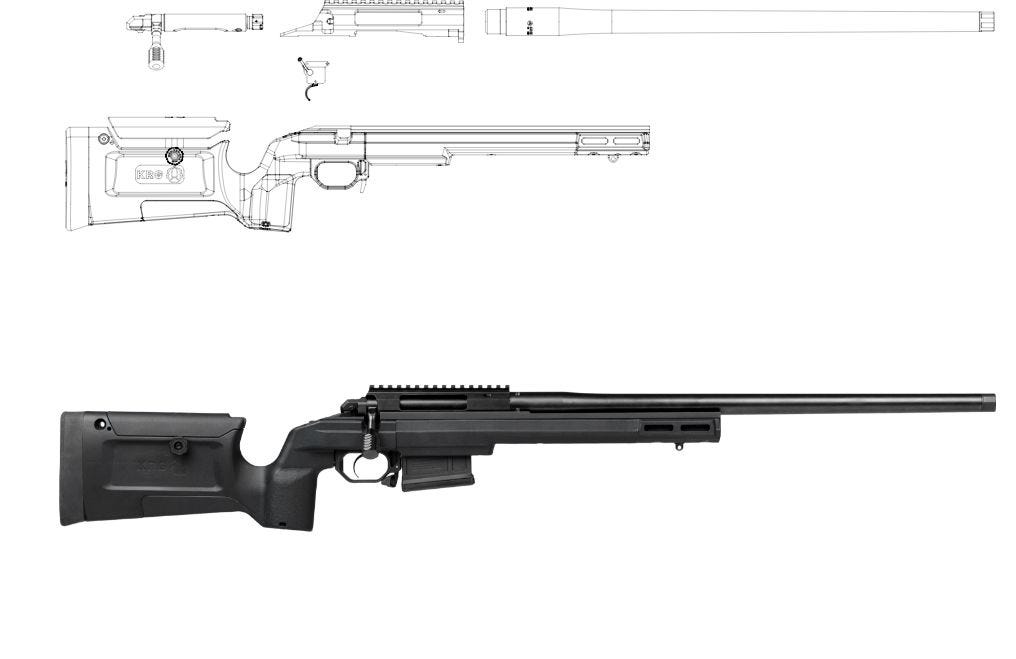

SOLUS

BRAVO RIFLE TECH SPECS

SPECIFICATIONS

KEY ATTRIBUTES

- Action: SOLUS Short Action

- Chassis: KRG Bravo

- Trigger: SOLUS Single Stage

- Caliber: 6 Creedmoor, 6.5 Creedmoor, 308 WIN

- Magazine: AICS detachable box magazine

FEATURES

- 60-degree bolt throw

- Integral 20 MOA bias scope base

- Adjustable cheek comb

KEY ATTRIBUTES

- Action: SOLUS Short Action

- Chassis: KRG Bravo

- Trigger: SOLUS Single Stage

- Caliber: 6 Creedmoor, 6.5 Creedmoor, 308 WIN

- Magazine: AICS detachable box magazine

FEATURES

- 60-degree bolt throw

- Integral 20 MOA bias scope base

- Adjustable cheek comb

initial assembly

Barrel Break-In Procedure

- Ensure the bore is free of any obstructions, oils or solvents. If unsure, insert a cleaning rod with jag and patch. Run the cleaning rod back and forth approximately 20 times or until clean, replacing patches as necessary.

- Obtain a rough zero for safety. The process for this depends on what optic you are using. Refer to the optic manual for instructions.

- Shoot approximately 50-60 rounds through your rifle in groups of 5 shots. Once you have shot 50-60 rounds through the barrel, follow the cleaning steps in section VIII "Bore Cleaning-Carbon Deposits"

- Zero your rifle and regularly track rounds fired and general accuracy achieved after break-in. Tracking can help you understand when maintenance needs to be performed. Replace barrel when accuracy starts to see permanent degradation.

bolt disassembly

The Solus bolt assembly can be readily disassembled without tools for cleaning and maintenance.

- With the bolt assembly removed from the action, grasp the Bolt Body with one hand and the Firing Pin Shroud with the other.

- Twist the Shroud approximately a ¼ turn clockwise. The Firing Pin assembly will snap free when the retention lugs enter their recesses.

- Once free, the Firing Pin Assembly can be removed from the bolt body.

- With the Firing Pin Assembly removed, the Bolt Head Retaining Pin can be taken out. Slight resistance may be encountered when removing the pin. Applying light pressure to drive the bolt head into the bolt body will allow the retaining pin to drop free.

- The bolt head can now be removed from the bolt body.

maintenance

After each use of your Solus rifle, thoroughly clean and lubricate it. Handling leaves fingerprints of moisture that can result in the formation of rust. Always wipe receiver, bolt assembly, and barrel with an oiled cloth after handling. All exterior metal surfaces should get a light coat of oil or rust preventative. Any good quality gun lube/CLP should work.

Abrupt temperature changes will cause the formation of condensation and moisture; special care to interior metal parts is needed to prevent rusting. Do not store the rifle overnight in the trunk of a vehicle. Long term storage should be done in a dehumidified gun vault or safe.

Before firing any firearm, be sure to remove all excess lubrication. The chamber and bore must be clean and free of all oils and lubricants.

SOLUS

PRODUCT OVERVIEW

SOLUS

GENERAL QUESTIONS

Our rifles are guaranteed to be Sub MOA from the factory.

The pull weight of the trigger varies between configurations and can be anywhere from 1.5lbs to 3lbs.

This varies on configuration can weigh between 6.5-12 lbs.

There are many opinions on this subject but the easiest place to start is intention, competitions require different equipment than hunting.

You will need to raise the comb up to remove the bolt. Make sure you remember or mark the adjustment height before moving it. Press the Bolt release on the left side of the receiver and pull the bolt out.

Align your caliber selection with the intended use of the rifle.

A minute of angle is a measurement used to determine the group size of a given shot. An MOA is 1/60th of a degree and measures 1.047" at 100 yards this measurement gets rounded to 1" for manual calculation and is known as "Shooter minute of angle".

Depending on the configuration, you will need a combination of the following: action wrench, barrel vise, barrel nut wrench, torque, and wrench.

A barrel vise is a clamping vise that utilizes bushings to provide anti rotation during installation.

Yes, all that is required is the proper bushing for the barrel.